Negative pressure unit for filtering asbestos contaminated room air via a 3-stage filter unit.

air capacity with filter max. 35000 m³/h

- Energy-efficient and performance-optimized fan with high capacity

- smooth and easy-to-decontaminate housing

- threefold sealed HEPA filter

- Easy, very low-emission filter change in 3 minutes

- Automatic soft start, even after power failure

- operating control and functional elements are shock-protected

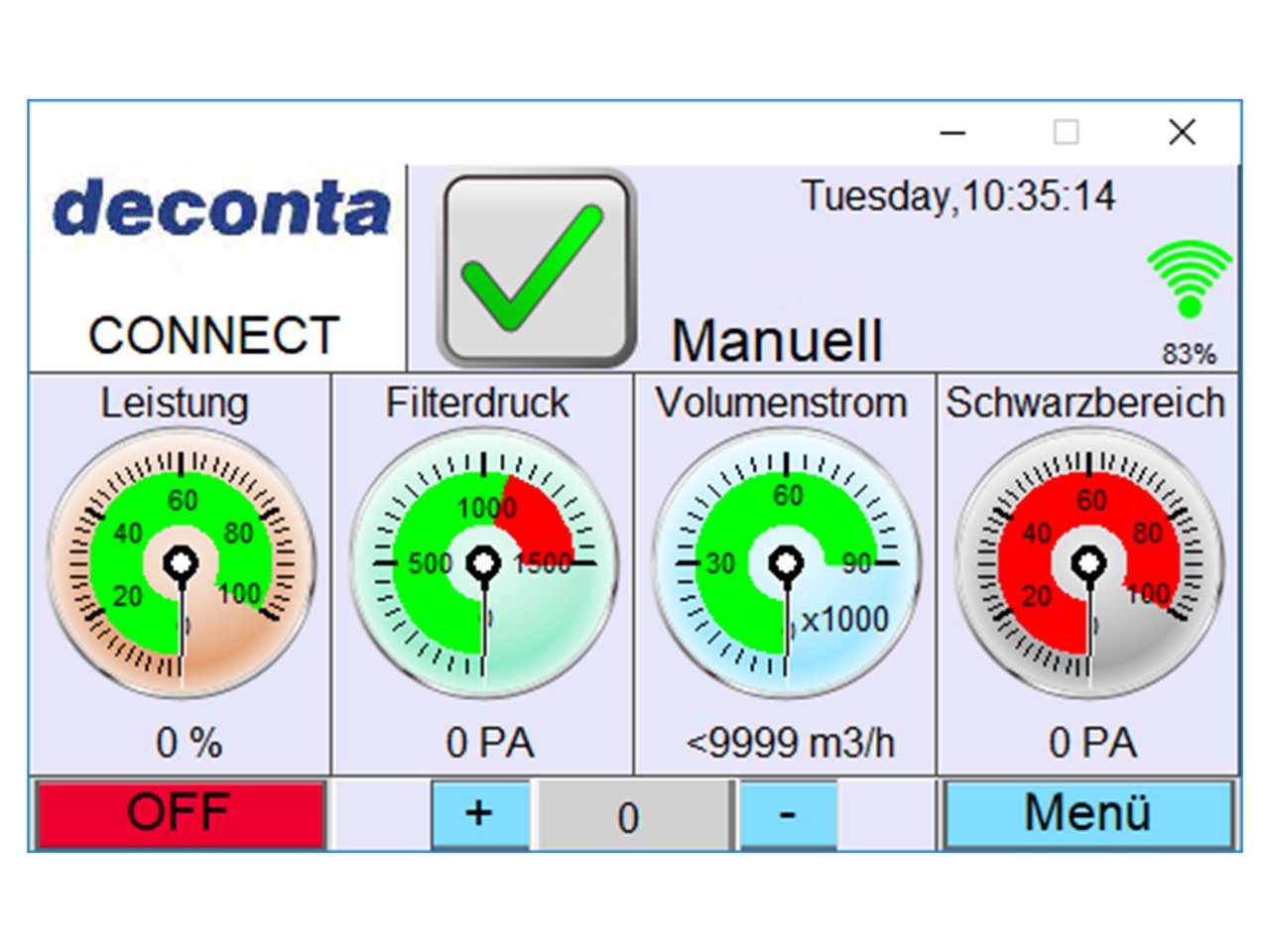

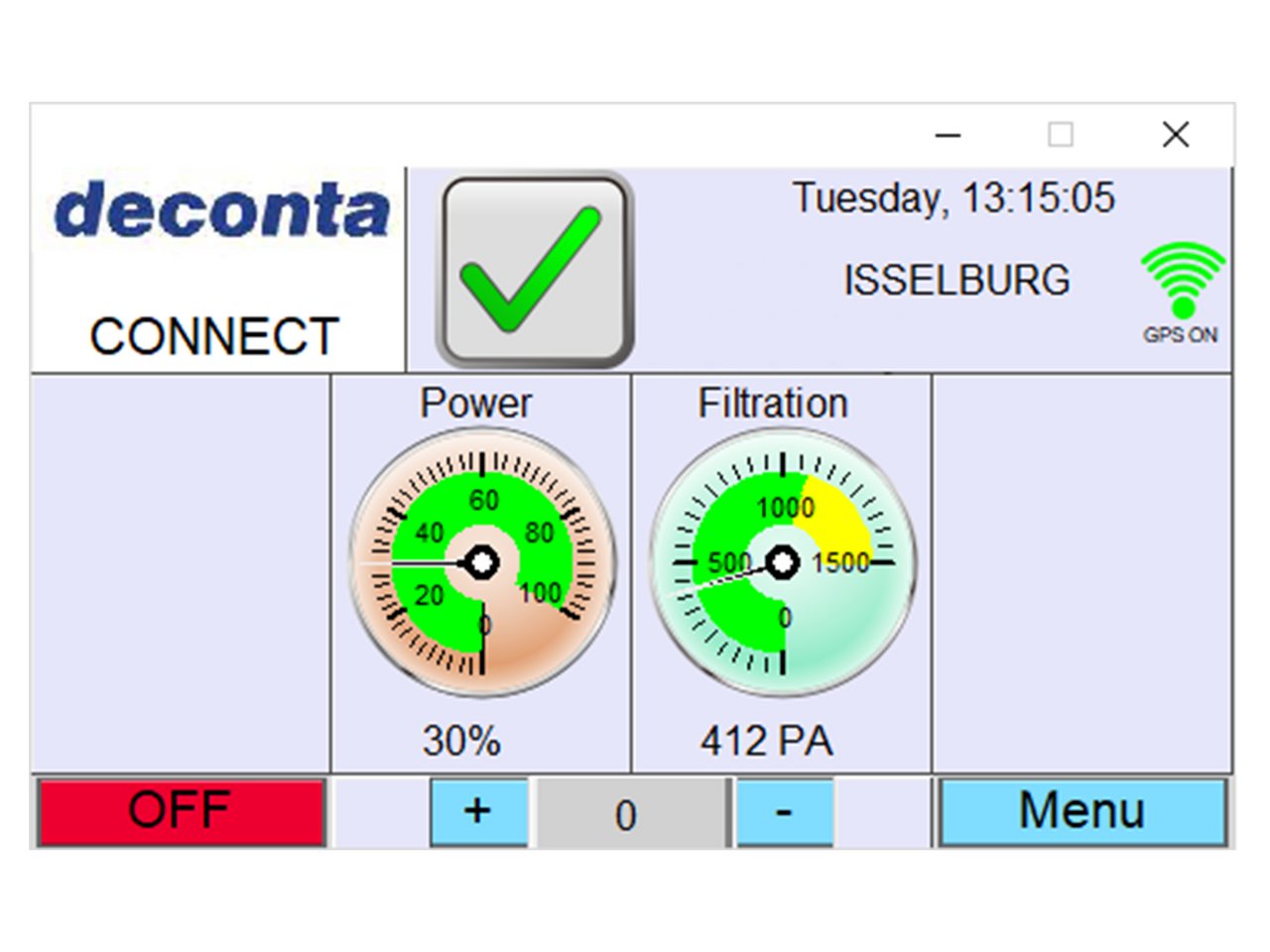

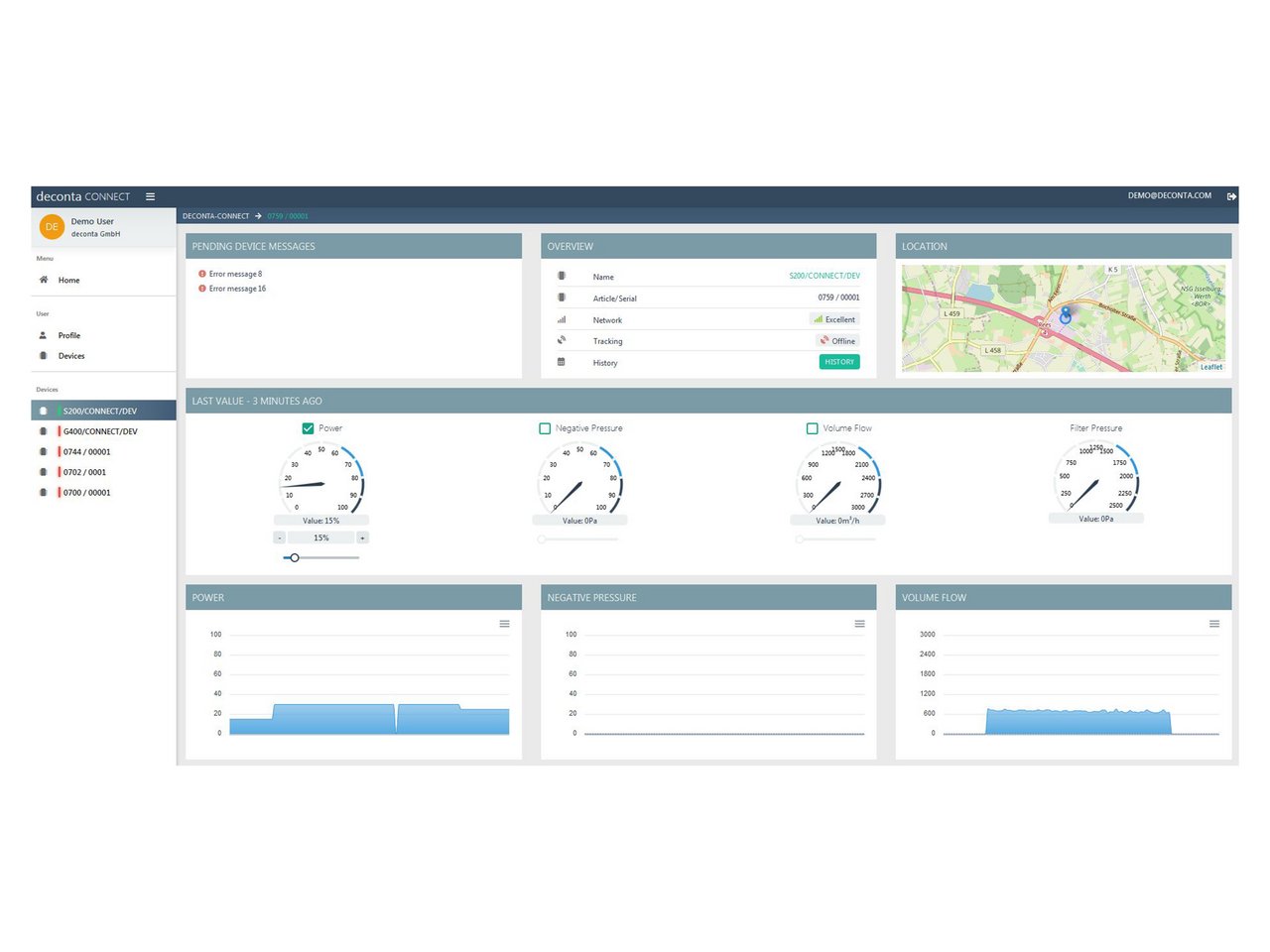

Control SRE connect

IoT (Internet of Things) => Devices with SRE connect control can be remotely controlled and monitored with any internet-enabled computer, mobile phone or tablet.

For power regulation, the negative pressure unit is supplied with a control via a touch display to measure and regulate the negative pressure and /or the volume flow.

The negative pressure is measured between the containment area and a reference point to be defined (adjacent rooms) and kept at the set point value by continuous speed control of the electric fan.

The volume flow is measured in the device and kept at the set point value by continuous speed control of the electric fan.

A manual control is also possible.

A filter sensor monitors the particle concentration in the exhaust air and triggers a visual and audible alarm if a value of ca. 100 particles per liter is permanently exceeded.

A necessary filter change is shown on the display.

Options

Technical data

All data on air performance and volume flows are taking into account a measuring tolerance of ± 15% based on the measuring range end value, determined in a multi-point measuring method with a calibrated vane anemometer.

- dimensions (LxWxH): 2990 x 1720 x 2380 mm

- weight incl. filter: ca. 1100 kg

- air capacity with filters: 35000 m³/h

- power connection: 400 V, 32 A

- power consumption: 20 A

- filter system 3-stage

- HEPA filter acc. to EN 1822 class H13

ATTENTION! Only original deconta HEPA filter ensure the machine safety!